Решение для роботов Abb Foundry

Решение для роботов Abb Foundry:

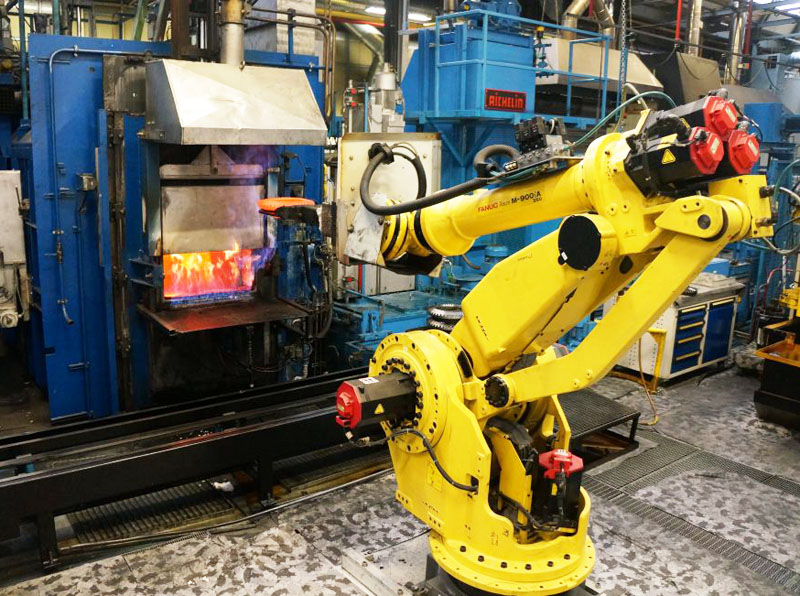

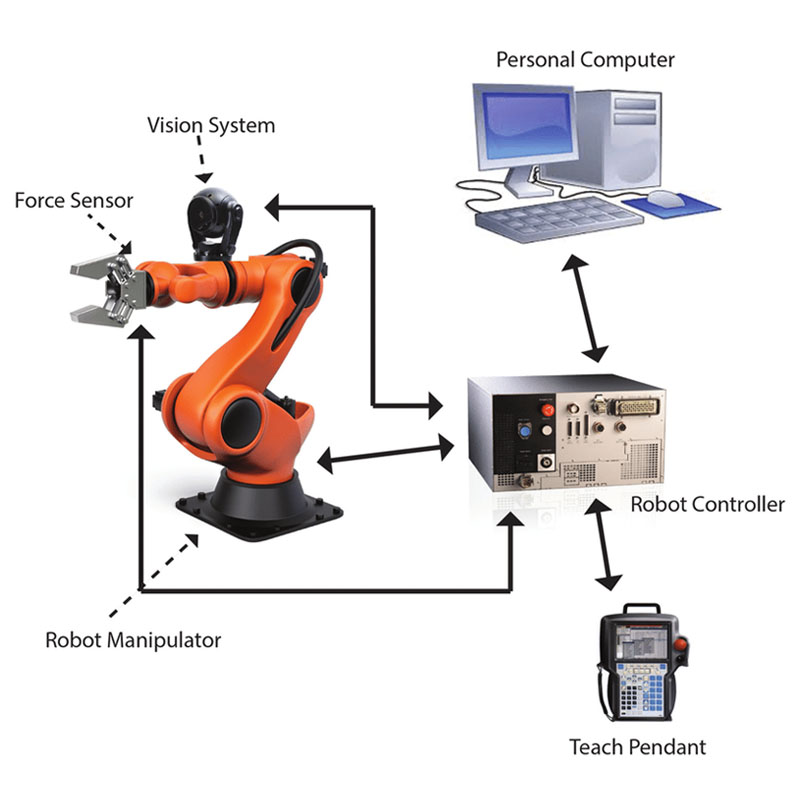

1. Расширенные возможности автоматизации: литейные роботы ABB оснащены расширенными возможностями автоматизации, что позволяет им выполнять сложные задачи с точностью и аккуратностью. Они могут с легкостью выполнять такие задачи, как разливка расплавленного металла, перемещение тяжелых компонентов и манипулирование формами.

2. Повышение безопасности работников: литейные роботы ABB помогают минимизировать риск для работников в опасных условиях литейного производства. Они могут выполнять задачи при экстремальных температурах, работать в ограниченном пространстве и переносить тяжелые грузы, снижая вероятность несчастных случаев и травм.

3. Повышенная производительность и эффективность: литейные роботы ABB значительно повышают производительность литейных операций. Они могут работать непрерывно, без перерывов, что приводит к увеличению производительности и сокращению времени цикла. Их быстрые и точные движения обеспечивают эффективный и оптимизированный рабочий процесс в литейном производстве.

Пожалуйста, свяжитесь с нами для получения подробных технических параметров.

Решение для роботов Abb Foundry:

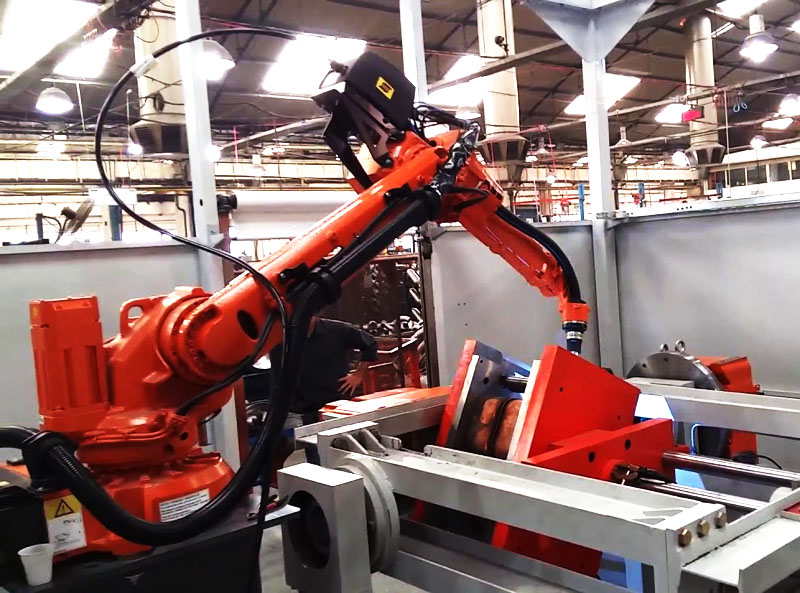

Роботы ABB Foundry в основном используются в таких отраслях, как погрузочно-разгрузочные работы, обслуживание машин, литье, литье под давлением и точечная сварка. Они предназначены для работы в суровых условиях и при высоких температурах. Эти роботы повышают производительность, качество и безопасность на рабочем месте. Они также используются в автомобильной промышленности для таких задач, как сборка, покраска и сварка. Роботы ABB Foundry также способны выполнять более сложные задачи, такие как 3D-печать, с точностью и аккуратностью. Они спроектированы так, чтобы быть гибкими и универсальными, чтобы адаптироваться к различным промышленным применениям.